Technological Advances of Metal Building Systems

In the past, metal building systems had a status quo to be warehouses or storage facilities that were simple and cookie-cutter. As the world is becoming more technologically driven, the construction industry has applied the opportunity to advance metal building systems. Today’s metal building systems are represented through sophistication that is highly customizable making it a likely candidate for almost any application. The advancements in design technology and fabrication capabilities have been key drivers in this initiative.

Modern metal building systems are now in the form of specialized medical facilities and office spaces. The customization features offer solutions that are tailored to the exact requirements of the project while remaining cost sensitive. Some customization items include complex geometric designs, varied roof systems, multiple elevations, and smooth integration with conventional materials.

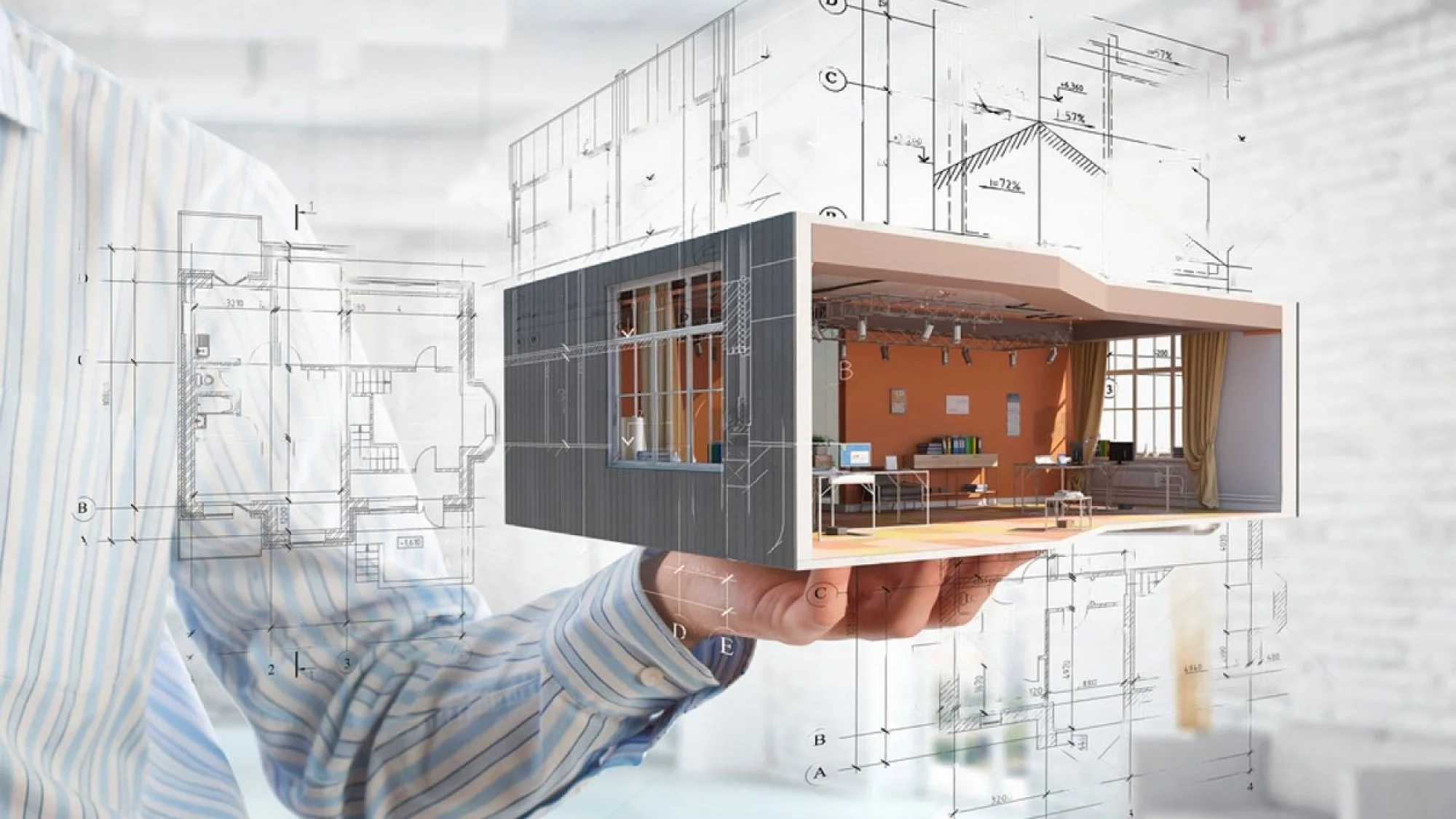

The construction industry has gone from 2D design to 3D modeling, enhancing the capabilities of metal building systems. Although many of us can visualize a structure in 3D, it is difficult to express that through words. This is where 3D modeling has cleared communication up and offered teams to better navigate the project from every angle and view. To combat accuracy and consistency, when changes are made in the 3D model, the job drawings are automatically updated.

Collaboration between 3D modeling and building information modeling (BIM) lowers costly field changes and delays. This is primarily due to technology detecting clashes between things like HVAC, electrical, structural, fire sprinkler systems, and sports equipment. This is a visualization tool teams use to see complete layout features like entries, exits, and internal systems.

Complexity is at the center of 3D visualization and planning when it comes to a provider’s capabilities. Not every project will require this advancement of technology, but for projects with a deep complexity of systems, features, or specialized functionality will lean on 3D modeling to maximize efficiency and accuracy.

At Brindley Construction, 3D modeling is a tool that is greatly valued. When needed, our project managers work together with our metal building manufacturers to produce the complex views of a project.

These technological advances are a holistic approach to metal building systems to increase accurate planning and execution from the early design phases to the final walk through. Metal building systems will continue to become more complex as society advances and technology becomes more revolutionary.

Have a project in mind?

Click Here!

Have a project in mind? Click Here!

Written by Dakota Ortega

Dakota serves as our Marketing Coordinator She attended The University of Tennessee Southern where she graduated early, earning her BS in Business Administration - Management in December of 2022. She earned her MBA from The University of Tennessee Southern in May of 2024. Dakota is dedicated to leading and directing Brindley Construction’s marketing needs with creativity at its forefront. She is an active member of Rotary Club of Pulaski and Giles County Chamber Diplomats.